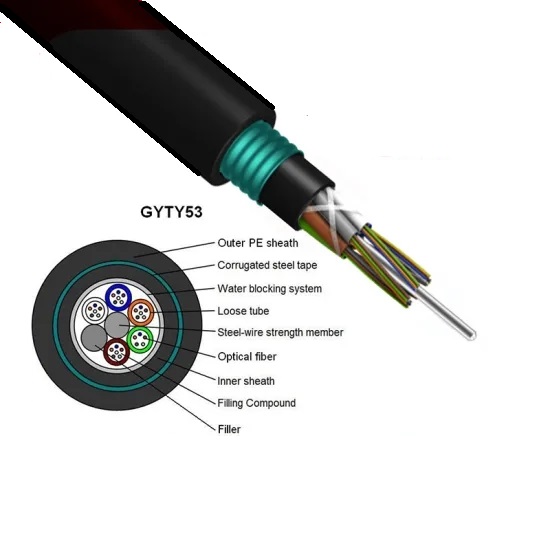

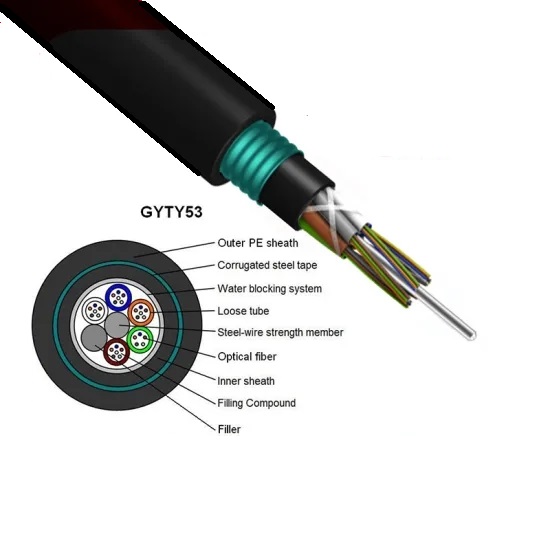

GYTY53

Outdoor Communication Large-Core Structure Duct Anti-Ant Single

Armoured Fiber Optical Cable

Constructure:

The structure of GYTY53 optical cable is that 250μm optical fiber

is sheathed in a loose tube made of high modulus material, and the

loose tube is filled with waterproof compound. The center of the

cable core is a metal reinforced core. For some optical fiber

cables, a layer of polyethylene (PE) needs to be extruded outside

the metal reinforced core. The loose tube (and filler rope) is

twisted around the central reinforcing core to form a compact and

round cable core, and the gaps in the cable core are filled with

water blocking fillers. A layer of polyethylene inner sheath.

Double-sided plastic coated steel tape (PSP) is longitudinally

wrapped and then extruded with polyethylene sheath to form cables.

Feature:

● Adopting "SZ" bidirectional layer twisting technology

● Filling water-blocking ointment step by step, water-blocking in

full section

● The steel (aluminum) belt has reliable bonding with the edge,

high strength, and no cracking when twisted

● Stable fiber excess length control

● After the cable is formed, the additional attenuation of the

fiber is almost zero, and the dispersion value does not change

● Excellent environmental performance, applicable temperature range

is -10 ℃ ~ + 70 ℃

Specification:

| Fiber Count | Nominal Diameter (mm) | Nominal Weight (kg/km) | Max Fibers per Tube | Max No. of (Tubes+fillers) | Allowable Tensile Load (N) | Allowable Crush Resistance (N/100mm) |

| Short Term | Long Term | Short Term | Long Term |

| 2~36 | 13.2 | 197 | 6 | 5 | 3000 | 1000 | 3000 | 1000 |

| 38~72 | 13.8 | 217 | 8 | 6 | 3000 | 1000 | 3000 | 1000 |

| 74~96 | 14.6 | 262 | 12 | 6 | 3000 | 1000 | 3000 | 1000 |

| 98~120 | 16.0 | 302 | 12 | 8 | 3000 | 1000 | 3000 | 1000 |

| 122~144 | 17.6 | 347 | 12 | 12 | 3000 | 1000 | 3000 | 1000 |

| >144 | Available upon customer’s request |

Note:

1. For flame retardant cable, outer sheath can be made of low-smoke

halogen-free (LSZH) material, and the type is GYTZS.

2.Upon customer’s request, cables with longitudinal color strip on

outer sheath can be offered. More details, please refer to GYTA

series.

3. Special cable structure can be designed and manufactured on

customer’s request.

Fiber Specifications

| Technical parameter of ITU-T G.652D (B1.3) single-mode optical

fiber |

| Characteristics | Conditions | Specified Values | Units |

| Optical Characteristics | | | |

| Mode field diameter (MFD) | 1310nm 1550nm | 9.2±0.4 10.4±0.8 | µm µm |

| Cut-off wavelength (λcc) | | ≤1260 | nm |

| Attenuation coefficient | 1310nm 1383nm 1550nm | <0.35 <0.35 <0.22 | dB/km dB/km dB/km |

| Macro bending loss | φ75mm, 100circles, at 1550nm | ≤0.1 | dB |

| Attenuation non-uniformity | | ≤0.05 | dB |

| Dispersion coefficient | 1288~1339nm 1271~1360nm 1550nm | ≤3.5 ≤5.3 ≤18 | Ps/(nm.km) Ps/(nm.km) Ps/(nm.km) |

| Zero dispersion wavelength | | 1300~1324 | nm |

| Max zero dispersion slope | | ≤0.093 | Ps/(nm2.km) |

| Group index of refraction (typical value) | 1310nm 1550nm | 1.466 1.467 | |

| Geometric characteristic | | | |

| Cladding diameter | | 125.0±1.0 | µm |

| Core/cladding concentricity error | | ≤0.8 | µm |

| Cladding non-circularity | | ≤1.0 | % |

| Coating diameter | | 245.0±10 | µm |

| Cladding/coating concentricity error | | ≤12.0 | µm |

| Coating non-circularity | | ≤8 | % |

| Diameter of colored coating | | 250.0±15 | µm |

| Mechanical characteristic | | | |

| Curling (radius) | | ≥4 | m |

| Proof stress | | >0.69 | Gpa |

| Coating strip force | Average value Peak value | 1.0-5.0 1.3-8.9 | N N |

| Dynamic stress corrosion susceptibility parameter (nd value) | | ≥20 | |

We produce and test cable comply with following standard

| Mechanical Performance |

| Max Tension Performance | IEC 60794–1-2-E |

| Max. Operation Tension | IEC 60794–1-2-E1 |

| Crush Test | IEC 6079 –1-2-E3 |

| Impact Test | IEC 60794–1-2-E4 |

| Repeated Bending | IEC 60794–1-2-E6 |

| Torsion Test | IEC 60794–1-2-E7 |

| Cable bend | IEC 60794–1-2-E11A |

| Attenuation Coefficient | ITU-T G.652 |

| Structural Test | IEC-60793-1-20 |

| Environmental Performance |

| Temperature Cycling | IEC 60794–1-2-F1 |

| Water Penetration | IEC 60794–1–2-F5B |

| Filing Compound Flow | IEC 60794-1-E14 |

Cable Core

The loose tubes are stranded around the central strength member

utilizing SZ. SZ stranding wraps the tubes in one direction for

several turns, then in the other direction.

Central Strength Member

The central strength member is made of steel It provides both

tensile and anti-buckling strength to the cable.

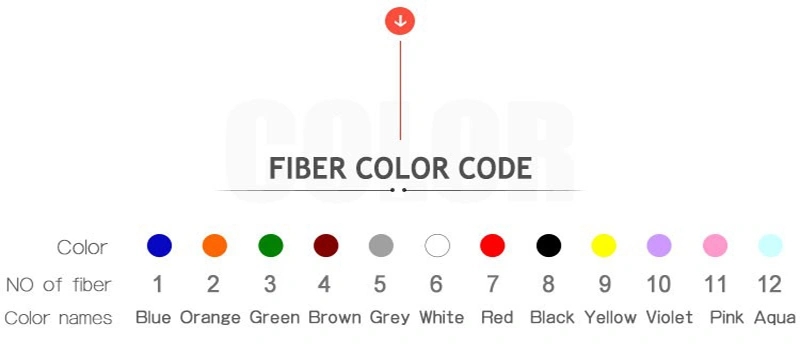

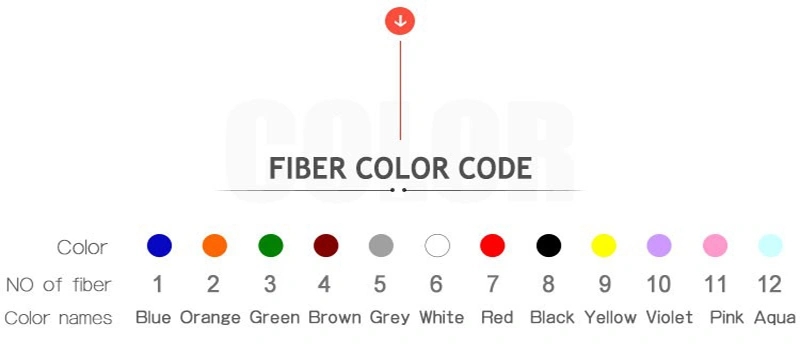

Loose Tube

Optical fibers are housed in jelly filled tube. The tube is

manufactured with industry standard PBT. It is colored for easy

identification according to the scheme shown above.

Water Blocking Material

Filling compound, the water blocking material between the loose

tube and the inner sheath protect cable from water intrusion.

Armour

Corrugated steel tape provide additional cable compression

strength, maximum anti-crush property, rodent protection and bullet

resistant performance.

Outer Jacket

A black high density polyethylene jacket is extruded over the cable

core and corrugated steel tape armor as the sheath.

Cable Sheath Marking

Each cable have the following information clearly marked on the

outer jacket of cables:

a. Name of manufacturer.

b. Year of manufacturer

c. Type of cable and fiber

d. Length mark (printing on each meter normally)

e. Or as customer’s requirements.

Application:

Suitable for overhead, pipeline, direct buried and other laying

methods

Related Products:

Company overview: